Problem

A paper mill wastewater facility was treating 940 tons of paper bags, recycled linerboard, and corrugating medium, daily. The mill was interested in improving wastewater operating efficiency and lowering operating expenses over their standard polymer usage. The plant was experiencing filamentous bacteria, solids, and bulking issues in the final clarifier. It was discharging 4,000 pounds of fiber per day into the Ohio River.

The facility was treating 2.8 MGD. Effluent from the mill was distributed between the two anaerobic ponds via a splitter box. The combined effluent from the anaerobic ponds filled an aerobic pond before clarification. After clarification, effluent was discharged to the river and the biosolids were processed by a belt press for thickening before landfill application.

Solution

A 9-month test was developed in which Bio Energizer® was administered to make nutrients more available to wastewater microorganisms, thereby stimulating natural bio-oxidation processes and enhancing sludge reduction. Samples were frequently collected at the effluent to test for BOD, COD, and total suspended solids (TSS).

Results

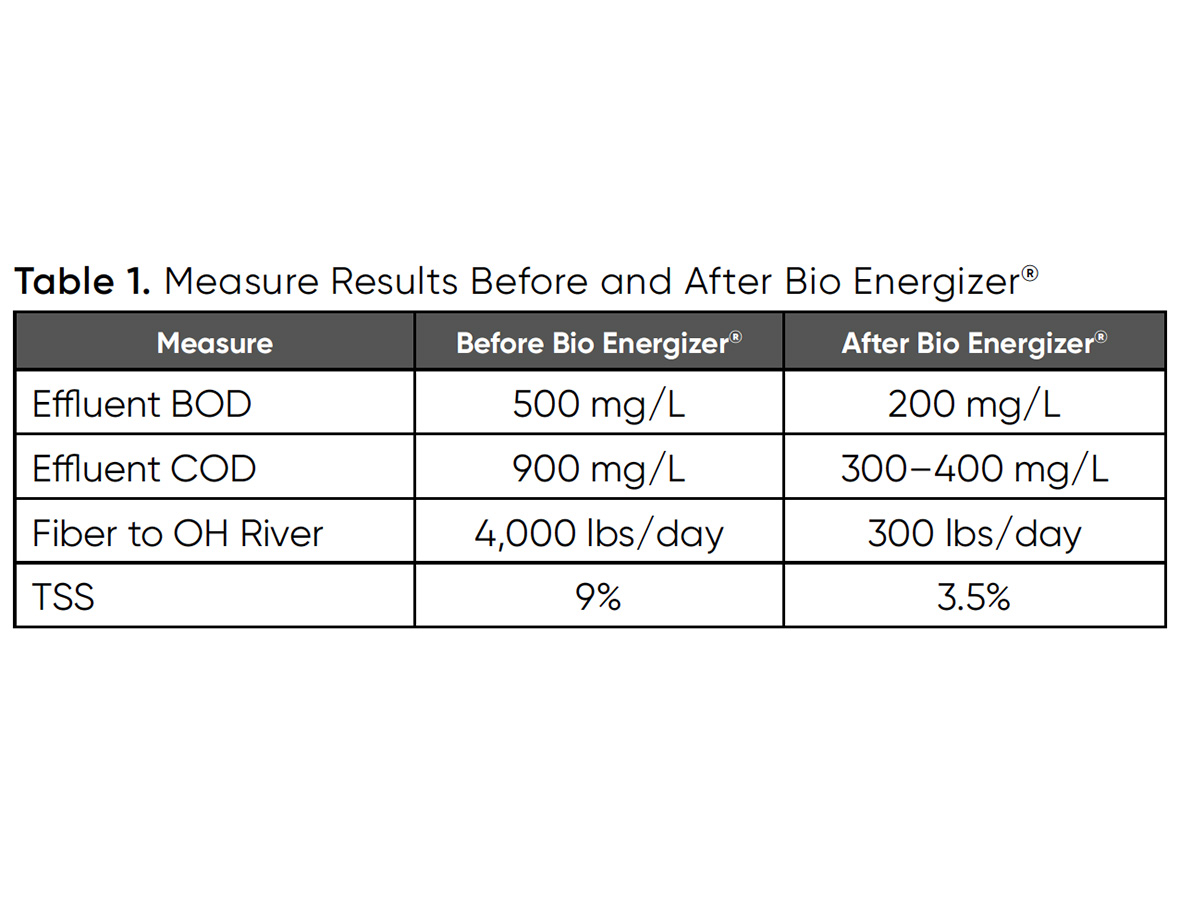

At the end of the 9-month period, the daily BOD and COD reduction improved (see Table 1).

Table 1. Measure Results Before and After Bio Energizer®

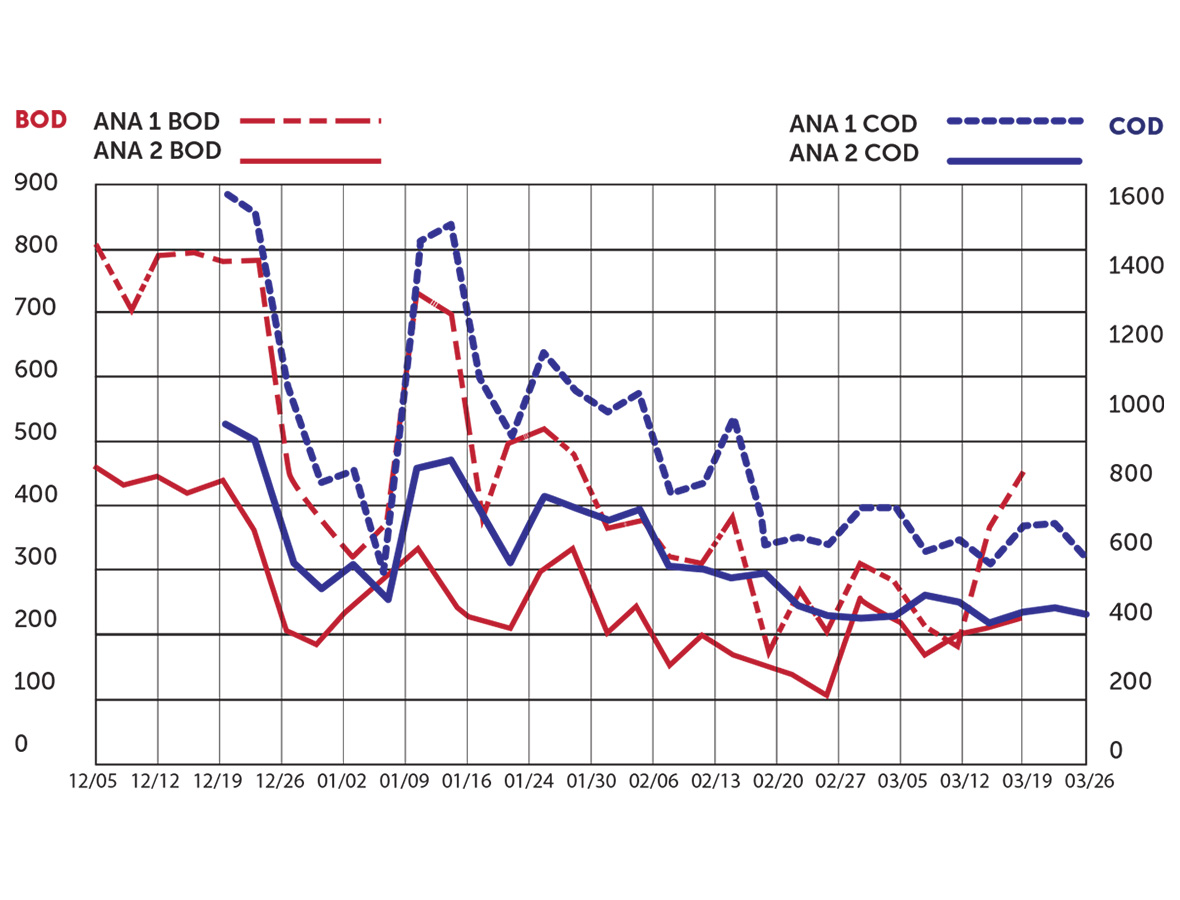

Chart 1. BOD/COD Discharges

Product Information

Bio Energizer® from Huma® Environmental is a formulation of nutrients, organic acids, natural biological stimulants, and energy systems that balance the natural microbial ecosystem to increase bio-oxidation capacity in lagoon systems. Bio Energizer® is a broad-spectrum bio-activator containing over 30 essential microbial growth-promoting ingredients.

Wastewater facility operators have been using Bio Energizer® for many years to cut their sludge-hauling costs. For more information, go to www.huma.us.