Summary

In this study, a one-year bioremediation plan featuring Bio Energizer® was implemented for a municipal wastewater treatment facility with 2 primary lagoons in which sludge depths had reached 5–7 feet. The lagoons were at risk of upset and wastewater processing capacity was reduced. Sludge levels were measured at baseline and quarterly. Sludge depth was biologically reduced by an average of 45%. This represented 17,810 dry tons of sludge that did not need to be mechanically removed and hauled to a disposal location, a potential savings of $6 million.

Problem

A California municipal wastewater treatment facility (WWTF) with 4 lagoons primarily processed municipal waste as well as several types of commercial/industrial waste, including waste from a tomato processing plant and a dairy processing plant, for a total of 2.8 million gallons a day. The WWTF operators determined that their 10-foot-deep lagoons had reached sludge depths of 5–7 feet, putting the lagoons at risk of upset and seriously impacting the facility’s wastewater processing capacity. A bioremediation plan was requested to reduce sludge levels, increase capacity, and return the system to a state of biological health.

Solution

Due to the high average sludge-blanket depth and the loss of the primary lagoon’s overall capacity, a biostimulant, Bio Energizer®, was selected to support the reduction of the organic solids in the system. Bio Energizer® is not a microbial product but a formulation of complexing agents, organic acids, natural biological stimulants, and nutrients that help balance the natural microbial ecosystem to increase bio-oxidation capacity. Bio Energizer® was added via peristaltic pump to the inlets of both Pond 1A and Pond 1B. Initially the dose applied was 7 ppm (7 gallons of product to 1,000,000 gallons of influent, assuming a typical Biochemical Oxygen Demand [BOD5] of 240 mg/L) and was eventually decreased 10 months later to 5 ppm. A maintenance dose of 3 ppm was established 2 months later.

Results

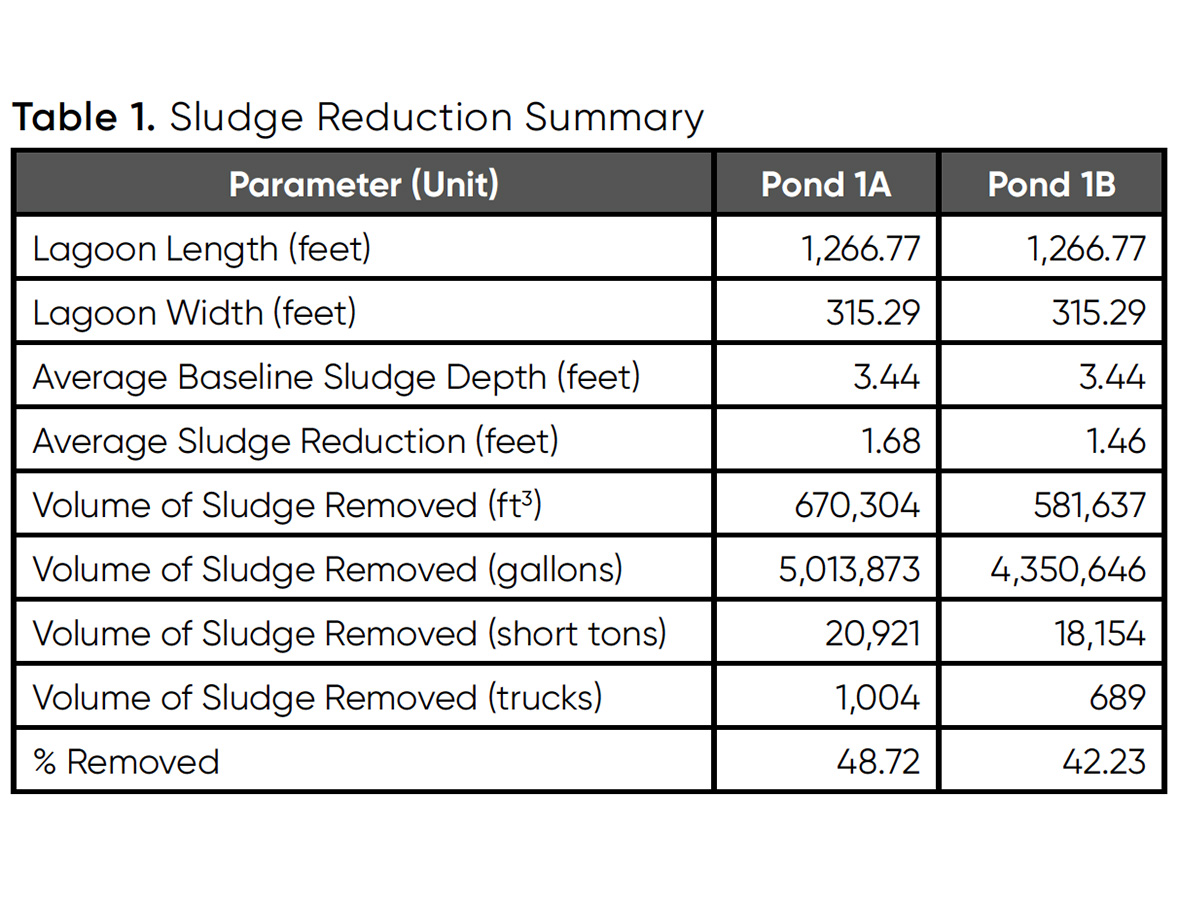

The baseline sludge levels were over 5 feet in 5 different locations in both Pond 1A and Pond 1B. On average, both ponds had 3.44 feet of sludge when the baseline sludge judge was completed. In November 2019, the average amounts of sludge removed were 1.68 ft for Pond 1A and 1.46 ft for Pond 1B, which accounts for reductions of 48% and 42% respectively. These percentages represent about 9,375,000 gallons of sludge or about 2,800 truckloads removed with very little capital investment.

Table 1. Sludge Reduction Summary

Conclusions

An additional 57.4 MG/Year of solids were treated in addition to what was removed. When adding the gallons of sludge reduced to the gallons of solids treated within the system, the total is 66.8 MG for the treatment time. Converting these gallons to 6% dry tons it comes out to 17,800 dry tons. At $340/ton (from previous customer study) for removal of dry tons, this represents a savings of $6,066,000. The calculation excludes the down time required to dredge the lagoons. This total was compared with an investment in product of $350,000, and it was found that the facility product investment was 5.8% of the potential dredging costs.

Product Information

Bio Energizer® is a balanced formulation of vitamins, trace nutrients, enzymes, organic acids, and biostimulants that stimulate the existing microbial community to greater metabolic capacity and efficiency. For more information, go to www.huma.us.