Objective

The objective of this field trial was for the grower to evaluate the ease of use and the effectiveness of 4 OMRI-Listed liquid Huma® organic crop nutrition products based on known field deficiencies.

Materials & Methods

The organic producer provided 2 80-acre plots of organic white corn in eastern Nebraska that was at the tassel growth stage. The Control plot was to continue to use her OMRI-Listed grower's standard fertilizer program, while the second plot, the Trial plot, would replace the grower's standard fertilizer program with OMRI-Listed Huma® organic products from posttassel stage through harvest.

The grower was supplied with 4 OMRI-Listed Huma® products pre-blended for application at the post-tassel growth stage on the Trial plot. These included OM Potassium (potassium 6%), OM Mag (magnesium 5%), OM Calcium (calcium 8%), and OM Micros (containing sulfur 5% and the following micronutrients: boron 0.40%, copper 0.16%, iron 4%, manganese 2%, molybdenum 0.128 %, and zinc 1%). In addition, Huma® Proud 3®, an organic, OMRIListed liquid foliar insecticide-miticide-fungicide was mixed and applied with the other products.

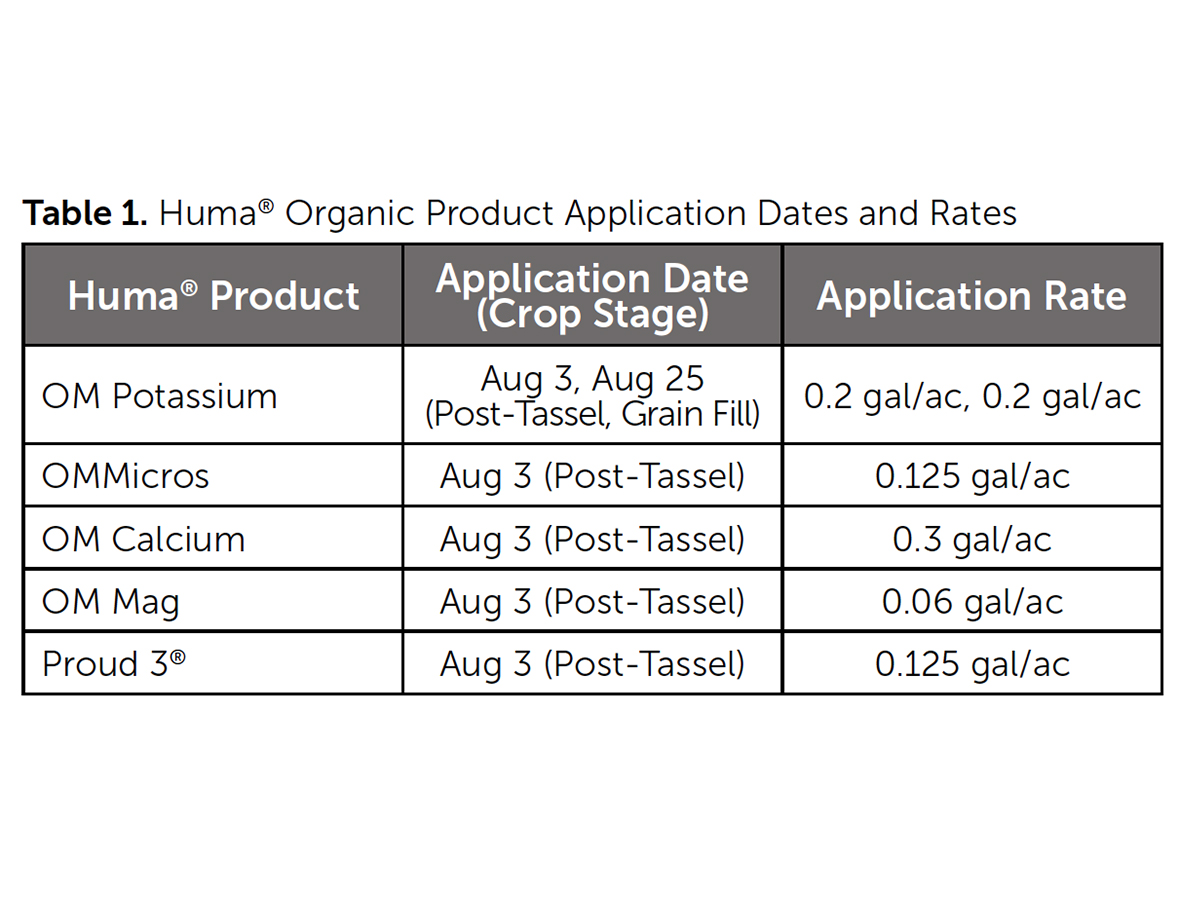

A second application of OM Potassium was applied at grain fill. (See Table 1 for rates.) All products tested and control products used were OMRI-Listed and approved for use in advance by Bruch's certification agency. Both corn plots had the organic fertilizer applied through foliar broadcast using a center-pivot irrigation system.

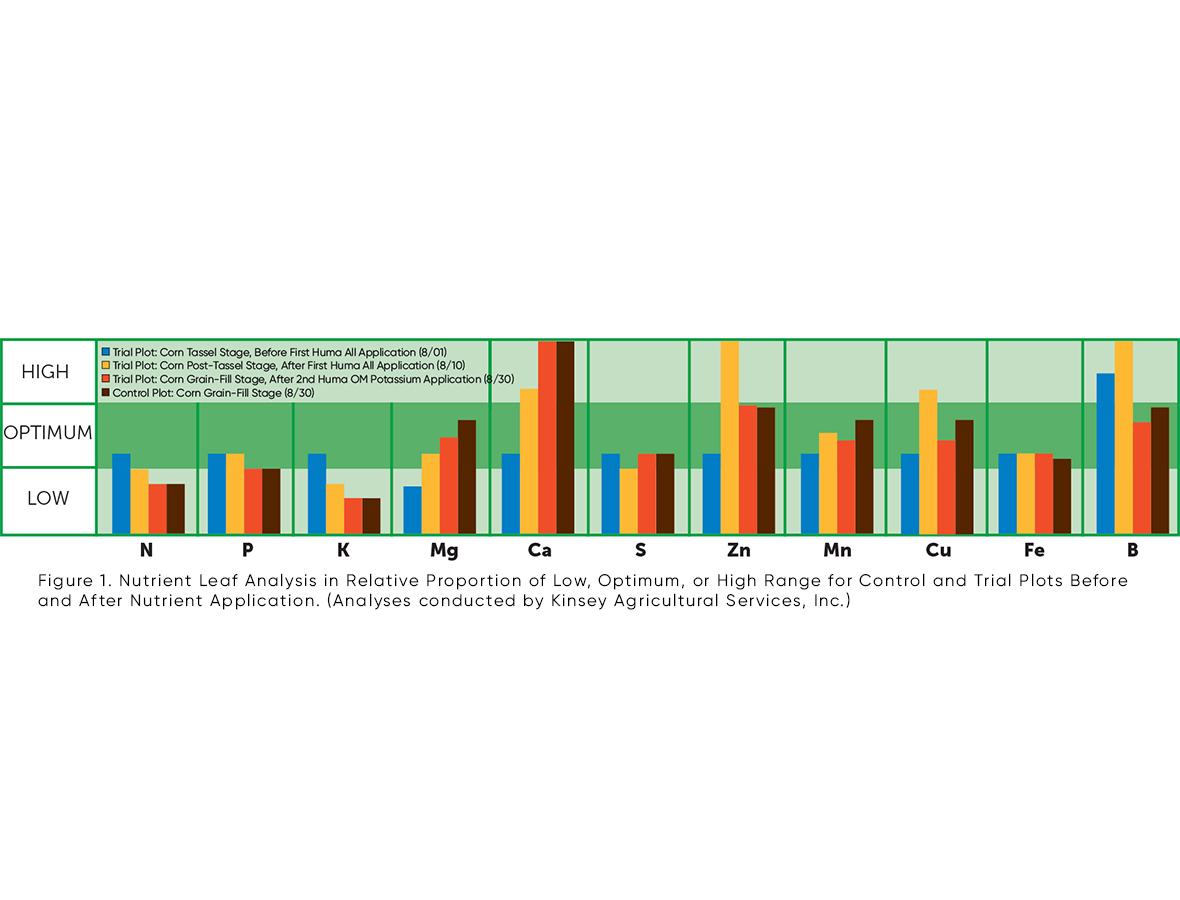

Plant tissue analyses for the Trial plot were conducted prior to application of the Huma® products (tassel stage), after the first application (post-tassel), and after the second OM Potassium application (grain fill). Analysis of the Control plot was conducted at the same time as the final Trial plot analysis (grain fill). (See Figure 1 for tissue analyses results.)

Table 1. Huma® Organic Product Application Dates and Rates

Results

Plant tissue analysis indicated that, in all instances, nutrients from the OMRI-Listed Huma® products were entering the plant as effectively as the grower's standard fertilizer program. Yield results for the Trial plot averaged 2–3 bushels per acre higher than the Control plot.

The grower reported product ease of use as being a major benefit, as the Huma® liquid products had low viscosity and did not clog the fertigation equipment for the pivot. Also, since the products could be applied with irrigation, no additional physical passes over the field were required for fertilizer application. The grower also commented that she really appreciated that all the specific nutrients were available and could be delivered within 10 days of deficiency identified by tissue analysis, when they could do the most good, and she was impressed with Huma® customer service, both in building a customized solution to reduce deficiencies in her organic white corn field and the partnership throughout the process.

Figure 1. Nutrient Leaf Analysis in Relative Proportion of Low, Optimum, or High Range for Control and Trial Plots Before

and After Nutrient Application. (Analyses conducted by Kinsey Agricultural Services, Inc.)

Conclusions

The trial demonstrated Huma® organic liquid products to be effective, easily applied, and flexible in terms of nutrient choices for organic white corn grown on a center pivot irrigation system.

Recommendations

The product application rates used in this trial proved to be appropriate for all but potassium, which tissue testing found to be low in both the Control and Trial plots. It is recommended that the potassium application rates for organic white corn be significantly increased for future trials. It is also recommended that the next field trial for this crop be conducted with a full Huma® nutrition program that is applied from preplant through to harvest.