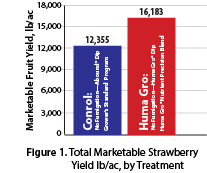

Huma Gro® Ultra-Precision™ Blend Plus Root Dip Increases Strawberry Yields 30%, Univ. of Calif.

Conducted by: Surendra K. Dara, PhD, University of California

Huma Gro® Products: Ultra-Precision™ Blend; plus root dip of Breakout®, Promax®, Vitol®, and Zap®

The purpose of this research project was to evaluate how a special blend of fertilizer solution and a root dip made of Huma Gro® products with Micro Carbon Technology® affect strawberry yield when compared with a control program of grower’s standard fertilizer and a competitor root dip product.

MATERIALS AND METHODS

Strawberry cultivar San Andreas was grown on 300-feet long bed plots at a University of California research center in Shafter, Calif., on a soil that was not fumigated. A total of two beds were used for this experiment. Each bed had six subplots of 30 ft. long with an 18 ft. buffer between each subplot. This conventional production did not receive pre-plant fertilizer.

At transplanting time, sprinklers provided irrigation water and then drip irrigation was used shortly after. Two root dipping treatments were tested: (1) the grower standard included 7 fl oz of Abound (azoxystrobin) fungicide in 100 gal of water for 4 minutes immediately prior to planting, and (2) the Huma Gro® root dipping solution contained 6.4 fl oz of Breakout®, 1.28 fl oz of Promax®, 1.28 fl oz of Vitol®, and 1.28 fl oz of Zap® in 10 gallons of water for 4 min immediately prior to planting.

The grower’s standard fertilizer program consisted of 20-10-0 (a combination of 32-0-0 urea ammonium nitrate and 10-34-0 ammonium phosphate) and potassium thiosulfate applied at weekly intervals through fertigation.

The special Huma Gro® fertilizer blend containing macro- and micronutrients plus biostimulant products, known as Ultra Precision Blend (UPB), was injected through drip 12 times during the growing season, while the grower standard fertilizer was applied 20 times during the same period. Two different mixtures of UPB fertilizers were used. The first blend (which was created based on needs identified by pre-plant soil analysis) was used from planting time till December, and the second blend (based on needs identified by soil and tissue analysis during active growth) was applied from December till the end of the season. UPB Blend #2 most notably contained boron, copper, and additional calcium that was not present in UPB #1.

The marketable fruit data is from only March 11 to May 11 harvests.

CONCLUSIONS

The Huma Gro® root dip and UPB fertilizer treatment yielded 30% more marketable strawberries than the grower standard fertilizer program. The 30% yield increase due to BHN fertilizer regime gave a net return of hundreds of dollars per acre, with a ROI ratio of over 3 to 1.

Click HERE to read the full report.

Related Posts

Earth Week: Celebrating All Creatures Small and Great

No matter how small the acts, or how small the actors, everything in our natural world connects, and everything makes a difference. I spend a lot of time reading to my granddaughters, and I’ve found that there are now many kid books about how to help the Earth (I’ve selected a few at the end

Jason Garcia on Commercial Vegetable Growing with Huma Gro®

With Larry Cooper Vegetable growers in Central Florida are preparing to get their beds ready for planting, so here’s my guide to how Huma Gro® can help growers get their best vegetable crops ever. Bed Preparation It’s become a pretty standard practice for Florida vegetable growers to fumigate their fields, then put down plastic and

Does Eutrophication cause Algae Blooms?

Eutrophication is the structural change of water ecosystems that is caused by excess nutrients. Eutrophication results in algal blooms and poor water quality. By Jael Batty In this article, we discuss what causes eutrophication, how it affects the environment, and how it is treated.