by Heather Jennings, PS

Bio Energizer® was added via peristaltic pump to the lagoon inlets. Initially the dose applied was 7 ppm (7 gallons of product to 1,000,000 gallons of influent, assuming a typical Biochemical Oxygen Demand [BOD5] of 240 mg/L) and was eventually decreased 10 months later to 5 ppm. A maintenance dose of 3 ppm was established 2 months later.

Sludge levels were measured at baseline and quarterly. Sludge depth was biologically reduced by an average of 45%. This represented 17,810 dry tons of sludge that did not need to be mechanically removed and hauled to a disposal location, a potential savings of $6 million. When compared with product cost, and it was found that the facility product investment was 5.8% of the potential dredging costs.

To view the report, click here.

For more information about Bio Energizer®, click here.

Related Posts

Does Eutrophication cause Algae Blooms?

Eutrophication is the structural change of water ecosystems that is caused by excess nutrients. Eutrophication results in algal blooms and poor water quality. By Jael Batty In this article, we discuss what causes eutrophication, how it affects the environment, and how it is treated.

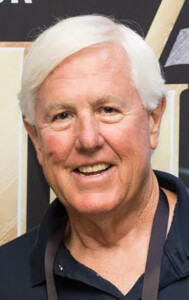

MVH’s Bruce Reid Receives the 2017 HPTA Above and Beyond Award

Bruce Reid, former majority owner and general manager of Mesa Verde Humates® (MVH), has been awarded the 2017 Humic Products Trade Association (HPTA) Above and Beyond Award. The Above and Beyond Award is presented annually to a hard-working individual whose effort and influence have contributed to HTPA’s mission. As a founding HPTA member who was

Making Memories by Making Hay

Making Memories by Making Hay A nostalgic look back at the labor, sweat, and family memories made during hay season — from hand-stacking square bales to the arrival of the game-changing round baler.