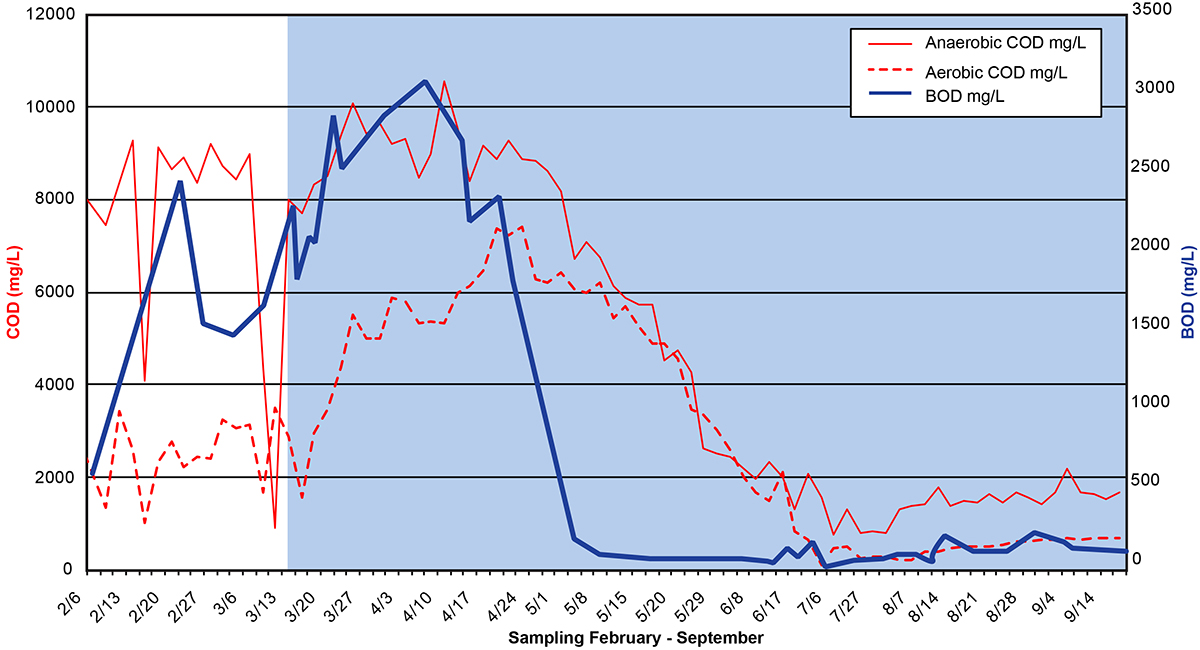

Within a few months of operation, a lagoon and spray field system at a corn processing plant in Indiana began giving off offensive odors. Chemical oxygen demand (COD) levels in the anaerobic and aerobic lagoons climbed to 8,000 mg/L and 4,000 mg/L respectively. The pH in the anaerobic lagoon was dropping dangerously low for methane production. Attempts to resolve the issues with bacteria, odor masking products, and lime were unsuccessful and short-term at best. Lime settled to the bottom of the lagoons, temporarily raising pH and reducing odors. The odor soon became unmanageable and an annoyance to neighbors.

In March, Probiotic Solutions® BIO ENERGIZER® was administered to the anaerobic lagoon at the rate of 1 gpd. Within 4 weeks of initial application, pH began rising and the odors were dramatically reduced.

BIO ENERGIZER® applied over a period of 30 days to the anaerobic lagoon system of the corn processing wastewater treatment plant resulted in biochemical oxygen demand (BOD) and COD reduction, odor reduction, and improved pH levels. COD levels in surplus effluent that was pumped to the city dropped from 8,000 mg/L to 200 mg/L, saving the plant $22,000 per month in excess COD charges.

Product Information

Probiotic Solutions® BIO ENERGIZER® is a formulation of nutrients, organic acids, natural biological stimulants, and energy systems that balance the natural microbial ecosystem to increase bio-oxidation capacity in lagoon systems. BIO ENERGIZER® is a broad-spectrum bio-activator containing over 30 essential microbial growth-promoting ingredients.

Related Posts

Ducks Walking on Water?

by Heather Jennings, PE Bio Energizer® Reduces Sludge Over 40% at Utah Municipal WTP The case study described below was a project that I worked on with a small-lagoon municipal system so overwhelmed with solids that state action was being taken. The ducks on the other side of the lagoon from me literally looked as

Working with ARA: the Voice of Ag Retailers

By Lyndon SmithPresident and CEO,Bio Huma Netics, Inc. The Agricultural Retailers Association (ARA) celebrated its 30th anniversary at the 2022 ARA Conference and Expo last week. It made me reflect on our long-standing ties with ARA, and the opportunities it provides us to assist agricultural retailers (ag retailers) with their challenges. Our association with ARA

This Week in Ag #83

Grandpa Fred never saw me. Despite the fact I was at his house nearly every day for over two decades. That’s because he was blind. From a farm accident. An anhydrous hose burst and shot the gas in his eyes.