Paper Mill Wastewater Treatment System

Project Summary

A paper mill wastewater treatment facility uses diammonium phosphate to maintain a healthy microbial population. These microorganisms, which break down the organic matter, require the correct concentration of available phosphorus, without which the microorganisms are unable to grow and reproduce.

In an effort to reduce costs while maintaining the wastewater treatment plant’s efficiency, the mill replaced the DAP with Probiotic Solutions® SUPER PHOS®. The daily dose of SUPER PHOS® was 75 kg versus 600 kg per day of DAP.

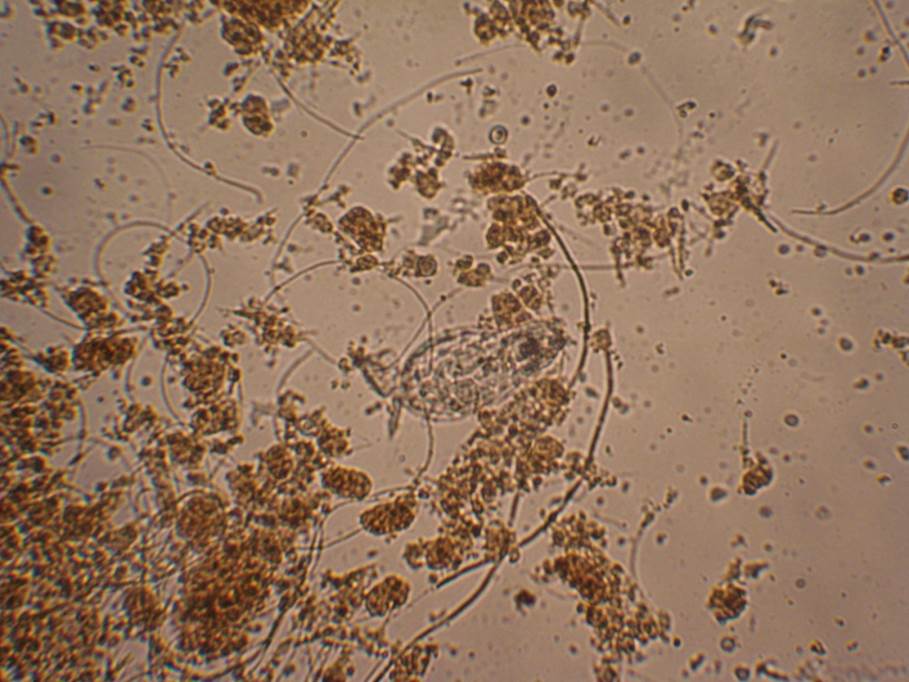

Microbial Microscopical Examination

Conclusion

Replacing DAP with SUPER PHOS® reduced chemicals cost, the required storage space, and the cost of labor associated with moving and dosing the product. Treatment efficiency was maintained even with the significant reduction in the phosphorous dose. Effluent COD was maintained at 200 mg/L. Furthermore, a microscopic analysis of the sludge showed the microbiology to be more active and regrowth was more vigorous following the addition of SUPER PHOS®. In addition, by reducing the quantity of phosphorus being added to the system has reduced corrosion and deposits in pipelines further reducing operation and maintenance costs.

Product Summary

In response to the reactivity of phosphorous in wastewater, Probiotic Solutions® developed a phosphorous product scientifically complexed with Micro Carbon Technology®* called SUPER PHOS®. Over the years this product has proven to save money and improve plant performance by maximizing phosphorous bioavailability with minimum phosphorous input. SUPER PHOS® is an essential component of energy––carrying phosphate compounds (ATP & ADP), nucleic acids, several essential coenzymes, and phospholipids.

SUPER PHOS® starts out as white phosphoric acid that is pre-complexed with organic acids to ensure maximum availability to microorganisms. SUPER PHOS® has proven itself in wastewater applications where maximum performance is required and minimum effluent phosphorous concentrations are demanded.

* The base of all of our Probiotic Solutions® products and the secret to our high efficiency rates is Micro Carbon Technology®. It’s a proprietary blend of very small organic molecules that greatly enhance existing microbial activity in wastewater to reduce sludge, cut down on odor, and control BOD and COD levels.

Related Posts

This Week in Ag #44

Now’s the time when holiday enthusiasts start dreaming of a White Christmas. But the marshmallow world created by falling snowflakes offers much more than a glistening backdrop for a Hallmark movie. And nobody choruses “Let it snow, let it snow, let it snow” louder than farmers. In the northern states, snow can account for 2/3 of

This Week in Ag #1

Curly fries, waffle fries, spicy fries or… regen fries? Soon, these may all be choices in the frozen foods aisle, at least if McCain Foods has a say in it. And as the world leader in prepared potato products, purchasing 6.8 million tons of spuds annually, McCain carries a strong voice. Their commitment to sustainability includes a pledge to have regen

“Trust but Verify”: China’s New Soybean Deal

China’s renewed commitment to purchase millions of tons of U.S. soybeans has farm country buzzing with optimism. But as past trade deals have shown, promises from Beijing don’t always sprout into reality.