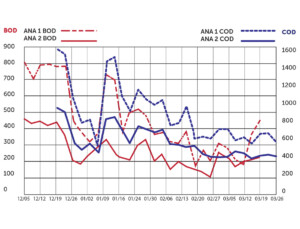

After consulting with staff from Probiotic Solutions®, the operator decided to inoculate the system with the broad-spectrum microbial product MicroPlex® JS to quickly seed the plant for the higher loading.

Through use of MicroPlex® JS, the plant quickly acclimatized to the higher load and met the system’s permit requirements. In addition, the operator is very happy with the results of the inoculation with MicroPlex® JS and how the plant continues to function during the camp’s open season. He plans to continue to use MicroPlex® JS at the start of each year.

Click here to download a PDF of the full case study.

Probiotic Solutions® MicroPlex® JS is a concentrated microbial product that is shipped as a two-part solution that is mixed with water prior to administration. The mix is added into the influent line to inoculate the system and feed on a daily basis for 30 days. Shock doses are added at the commencement of the inoculation period. For more information, go to www.probiotic.com.

Related Posts

Solids Destruction Efficiency Using BIO ENERGIZER®

A small Missouri Sewer District operated a single wastewater lagoon that treated approximately 10,000 gallons per day of municipal sewage. The lagoon was in need of sludge removal as it had not been dredged since it was constructed in the ‘70s. By treating the lagoon with Bio Energizer®, the District saw improvement in water clarity,

Bio Energizer® Reduces Cost and Turbidity in Paperboard Lagoons

A paper mill wastewater facility was treating 940 tons of paper bags, recycled linerboard, and corrugating medium, daily. The mill was interested in improving wastewater operating efficiency and lowering operating expenses over their standard polymer usage. The plant was experiencing filamentous bacteria, solids, and bulking issues in the final clarifier. It was discharging 4,000 pounds

Recycled Sewage: What Are We Putting on Our Farmland?

By Jael Batty Sewage sludge is a controversial input for farmers to use. Considering the toxins in today’s wastewater, are our treatments and regulations effective in eliminating micropollutants from sludge?