Location: Louisiana

A large sugar refinery struggled with elevated BOD and COD values in its wastewater treatment lagoons due to the sugar refinery process. The lagoon wastewater system capacity was 25 million gallons with an influent of 1.25 million gallons per day. The wastewater system also suffered from accumulating sludge as well as significant odor issues. The sugar refinery had a history of periodically being unable to meet its National Pollutant Discharge Elimination System (NPDES) permitting requirements.

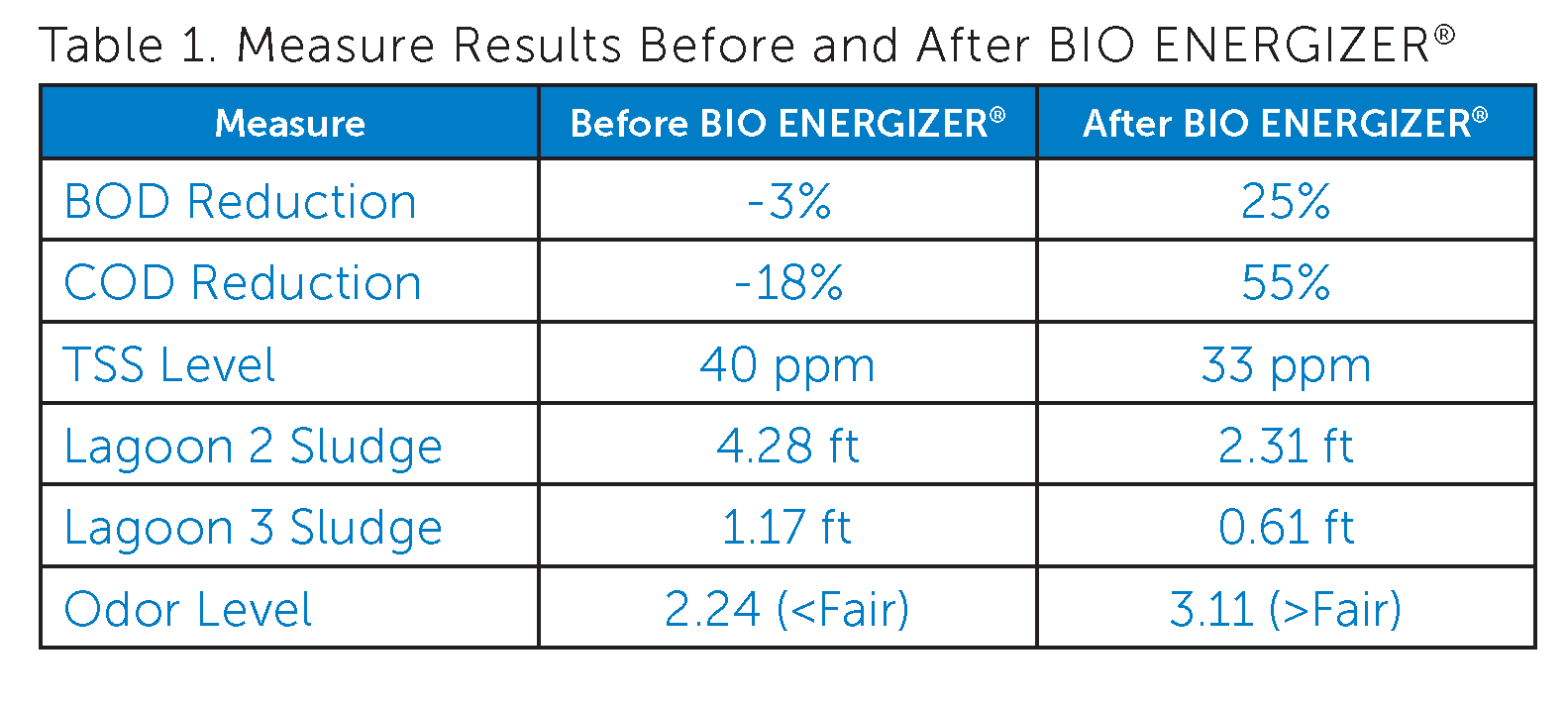

Probiotic Solutions® BIO ENERGIZER® applied to a sugar refinery wastewater lagoon system over 9 months resulted in reduced accumulated sludge, TSS, and odors, with improved BOD and COD reduction.

Read the full report in English online

Read the full report in Spanish online

Download the full report PDF in English

Download the full report PDF in Spanish

Related Posts

Use of Biostimulants for Upset Recovery in Paper Mill Wastewater Systems

By Heather Jennings, PE Two specific Probiotic Solutions® liquid bioremediation products were used at a large-scale paper mill in China to address system upsets caused by hydraulic loading from new upstream processes. The products involved are Bio Energizer® (BE)—a scientific formulation of organic acids, buffers, natural biological stimulants, micronutrients, and energy systems—and Micatrol® (MT), a

It’s ALIVE!

by Heather Jennings, PE . . . the lagoon sludge layer, that is. I’ve seen many lagoons full of sludge, and the general attitude I find in the water industry is that the sludge layer is inert and really can only be mechanically dredged. To a certain point, that is correct: sand, soil, grit, plastics—basically

Pulp and Paper Wastewater Solutions

Experience the world’s most efficient wastewater remediation products, for operational stability of pulp and paper wastewater treatment facilities.