A paper mill wastewater facility was treating 940 tons of paper bags, recycled linerboard, and corrugating medium, daily. The mill was interested in improving wastewater operating efficiency and lowering operating expenses over their standard polymer usage. The plant was experiencing filamentous bacteria, solids, and bulking issues in the final clarifier. It was discharging 4,000 pounds of fiber per day into the Ohio river.

The combined effluent from two anaerobic ponds filled an aerobic pond before clarification. After clarification, effluent was discharged to the river and the biosolids were processed by a belt press for thickening before landfill application.

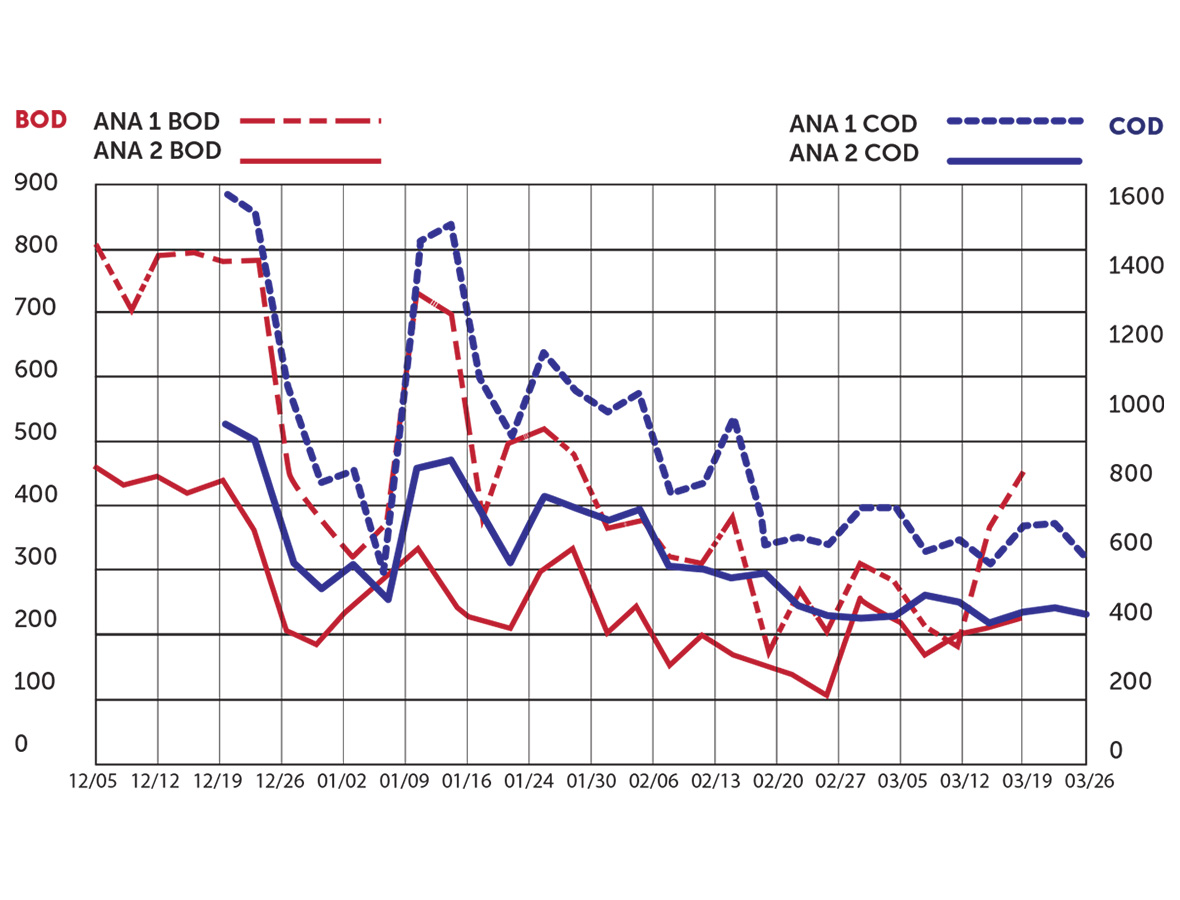

A 9-month test was developed in which Huma Environmental® BIO ENERGIZER® was administered to make nutrients more available to wastewater microorganisms, thereby stimulating natural bio-oxidation processes and enhancing sludge reduction. BIO ENERGIZER® applied over a period of 9 months resulted in reduced filamentous bacteria, bulking issues, and total suspended solids (TSS.) Turbidity in the effluent dramatically improved with $50,000 in polymer savings in the final clarifier. Additionally, fiber discharge was reduced, as were the BOD and COD levels in the effluent.

Huma Environmental® BIO ENERGIZER® is a formulation of nutrients, organic acids, natural biological stimulants, and energy systems that balance the natural microbial ecosystem to increase bio- oxidation capacity in lagoon systems. Wastewater facility operators have been using BIO ENERGIZER® for many years to cut their sludge-hauling costs.

Related Posts

The Huma Gro Farmer Podcast: Episode 8—Tank-Mixing Fertilizers and Other Agrochemicals – Blog

This Week in Ag #66

When asked if he was finished with planting, dad would frequently respond by saying, “the first time.” His cynicism aside, replant decisions can be difficult. This year, too many growers are faced with that decision. If you plant when the soil is cold and wet, you’re inviting problems. But even if you plant in good soil conditions,

From the Field: Huma® Improves Soil Health and Strawberries in Guatemala

In the highlands of Guatemala, near the capital, is a small stronghold for berries. Strawberry production in Guatemala covers about 3,000 hectares in total, yet it yields nearly 14,000 tons of fresh strawberries annually, with 7,000 tons exported to neighboring countries. During my previous visits to Guatemala, I often passed by local strawberry farms, which