A paper mill wastewater facility was treating 940 tons of paper bags, recycled linerboard, and corrugating medium, daily. The mill was interested in improving wastewater operating efficiency and lowering operating expenses over their standard polymer usage. The plant was experiencing filamentous bacteria, solids, and bulking issues in the final clarifier. It was discharging 4,000 pounds of fiber per day into the Ohio river.

The combined effluent from two anaerobic ponds filled an aerobic pond before clarification. After clarification, effluent was discharged to the river and the biosolids were processed by a belt press for thickening before landfill application.

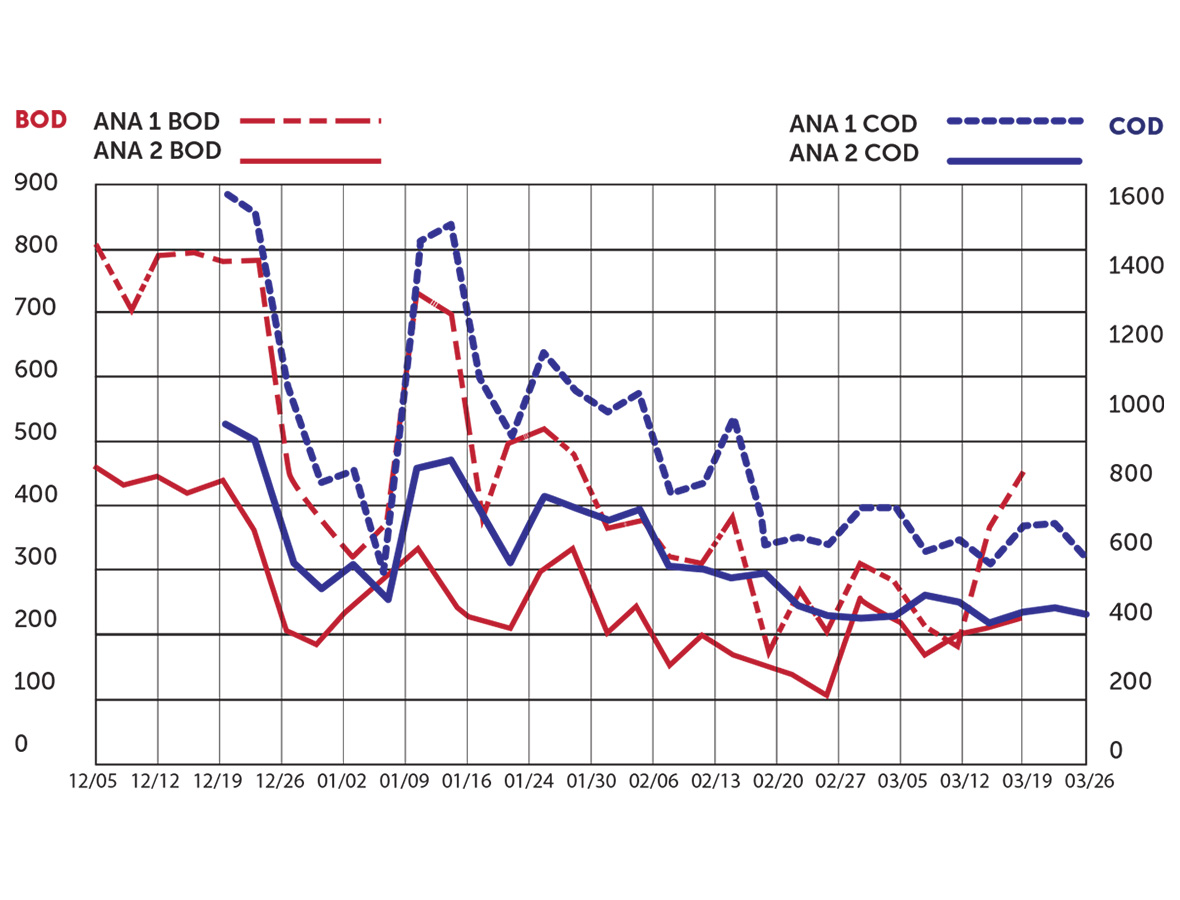

A 9-month test was developed in which Huma Environmental® BIO ENERGIZER® was administered to make nutrients more available to wastewater microorganisms, thereby stimulating natural bio-oxidation processes and enhancing sludge reduction. BIO ENERGIZER® applied over a period of 9 months resulted in reduced filamentous bacteria, bulking issues, and total suspended solids (TSS.) Turbidity in the effluent dramatically improved with $50,000 in polymer savings in the final clarifier. Additionally, fiber discharge was reduced, as were the BOD and COD levels in the effluent.

Huma Environmental® BIO ENERGIZER® is a formulation of nutrients, organic acids, natural biological stimulants, and energy systems that balance the natural microbial ecosystem to increase bio- oxidation capacity in lagoon systems. Wastewater facility operators have been using BIO ENERGIZER® for many years to cut their sludge-hauling costs.

Related Posts

BHN Welcomes Rich Lamar to the Humic Research Team

On May 1, 2019, Dr. Richard Lamar joined Bio Huma Netics, Inc. (BHN) as Senior Director of Humic Research. He brings a tremendous amount of skills, experience, and knowledge of humic substances to BHN. Dr. Lamar has a B.S. in Biology from the University of Miami, a M.S. in Forestry from Mississippi State University, and...

This Week in Ag #13

Corn came screaming out of the ground in just five days on my farm at Agricenter International in Memphis. Other than the seed and herbicide, I’m using 100% Huma® products. My belief is that you don’t just farm the crop, you farm the soil. These Mid-South soils have low organic matter levels, so the pre-plant application...

This Week in Ag #47

Nitrogen Use Efficiency has quickly become part of the vocabulary surrounding sustainability. But NUE is more than just a buzzword or another fancy acronym. NUE is the benchmark for nitrogen management. You’ll often see it used to measure the amount of nitrogen used to produce a bushel of grain. NUE is a pillar for calculating...