Rural Colorado Town Uses BIO ENERGIZER® to Reduce Wastewater Lagoon Sludge and Save Money

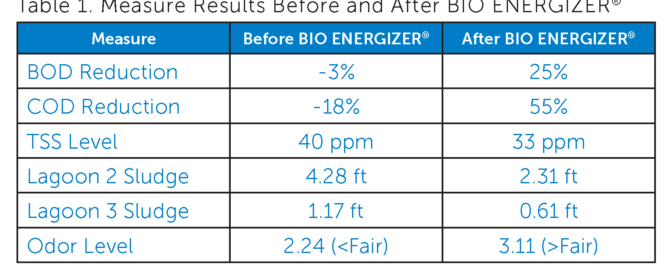

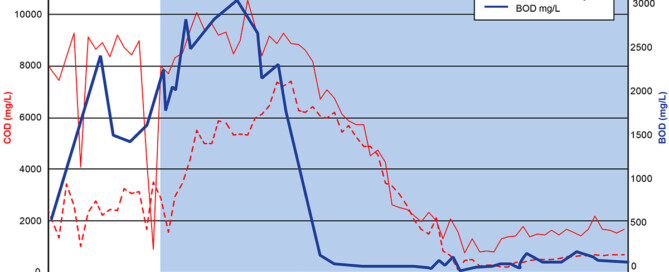

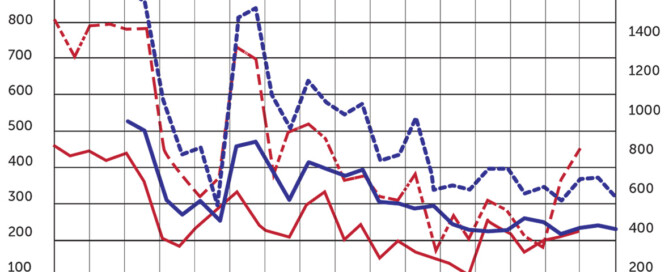

The wastewater treatment plant superintendent for a rural Colorado town of about 500 people noticed that the plant’s three wastewater lagoons were filling with sludge, but he was dealing with budget constraints. The town’s population fluctuates throughout the year, and the varied loading was affecting system performance. Continue reading