Wastewater treatment is an area that often garners less attention from mill owners than other areas within the mill. By maintaining a healthy microbial population within the biological portion of the wastewater treatment system, the treatment facility can ensure that it is operating at peak performance. Providing the necessary required nutrients in a bioavailable form is key to accomplishing the goal to meet regulatory statutes, improve system efficiency, and lower expenses.

In response to the reactivity of phosphorous in wastewater, Huma® Environmental developed a phosphorous product scientifically complexed with Micro Carbon Technology® called SUPER PHOS®. Over the years this product has proven to save money and improve plant performance by maximizing phosphorous bioavailability with minimum phosphorous input. SUPER PHOS® is an essential component of energy- carrying phosphate compounds (ATP & ADP), nucleic acids, several essential coenzymes, and phospholipids. SUPER PHOS® starts out as white phosphoric acid that is pre-complexed with organic acids to ensure maximum availability to microorganisms. SUPER PHOS® has proven itself in wastewater applications where maximum performance is required and minimum effluent phosphorous concentrations are demanded.

Bio Energizer®

Bio Energizer® significantly improves systems’ ability to recover after an “upset” condition, such as when systems experience instantaneous high COD or hydraulic loading, or experience high-toxicity events. The microbiology recovers quicker than is typical, leading to improved COD removal and settling, which improves water clarity and quality. Bio Energizer® improves, buffers, diversifies, and strengthens the microbiology in the system allowing the biochemical system to accommodate the “events” and maintain treatment efficiency.

Case Studies

Super Phos® Lowers Papermill Operating Costs in China

Problem The existing wastewater treatment system uses 600 kg/day of diammonium phosphate (DAP) to provide the needed phosphorus concentration to maintain a healthy microbial population to treat wastewater. These microorganisms break down the organic matter being discharged from the paper processing facility. Without the correct concentration of available phosphorus, the microorganisms are unable to grow...

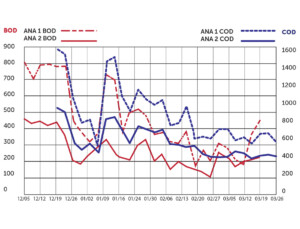

Bio Energizer® Reduces Costs and Turbidity in Paperboard Lagoons at Kentucky Papermill Wastewater Facility

Problem A paper mill wastewater facility was treating 940 tons of paper bags, recycled linerboard, and corrugating medium, daily. The mill was interested in improving wastewater operating efficiency and lowering operating expenses over their standard polymer usage. The plant was experiencing filamentous bacteria, solids, and bulking issues in the final clarifier. It was discharging 4,000...

Blog Posts

Use of Biostimulants and Buffers for Upset Recovery in Paper Mill Wastewater Systems

By Heather Jennings, PE Industrial pulp and paper wastewater is considered one of the more challenging waters to treat using biological methods, which depend on microbial activity to effectively remediate the wastewater. Wastewater treatment systems are often influenced/impacted by increased hydraulic and/or COD (chemical oxygen demand) loading as mills add new chemicals or otherwise modify...

Pulp and Paper Wastewater Solutions

Experience the world’s most efficient wastewater remediation products, for operational stability of pulp and paper wastewater treatment facilities.

Bio Energizer® Reduces Cost and Turbidity in Paperboard Lagoons

A paper mill wastewater facility was treating 940 tons of paper bags, recycled linerboard, and corrugating medium, daily. The mill was interested in improving wastewater operating efficiency and lowering operating expenses over their standard polymer usage. The plant was experiencing filamentous bacteria, solids, and bulking issues in the final clarifier. It was discharging 4,000 pounds...